DAN AGRO

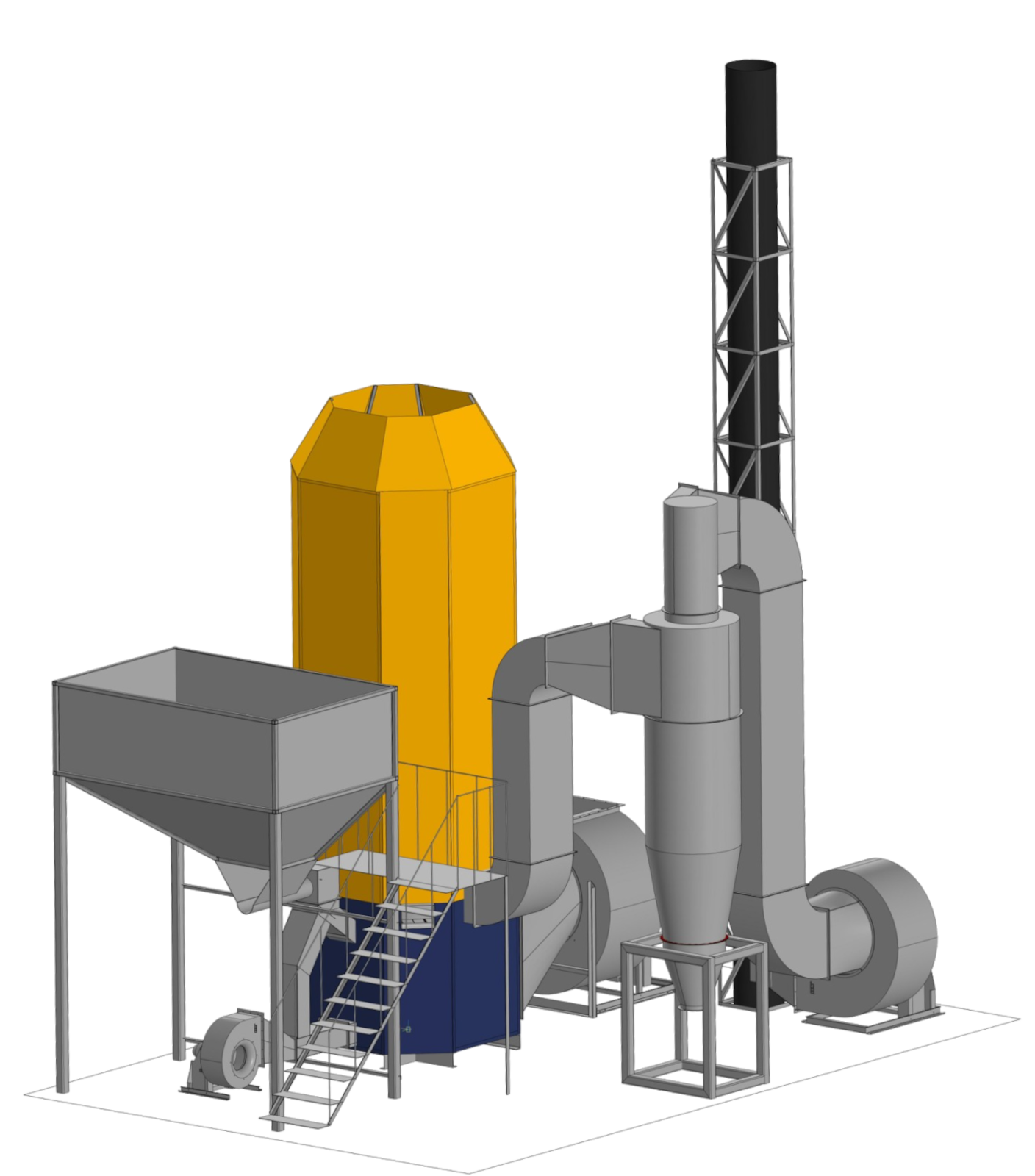

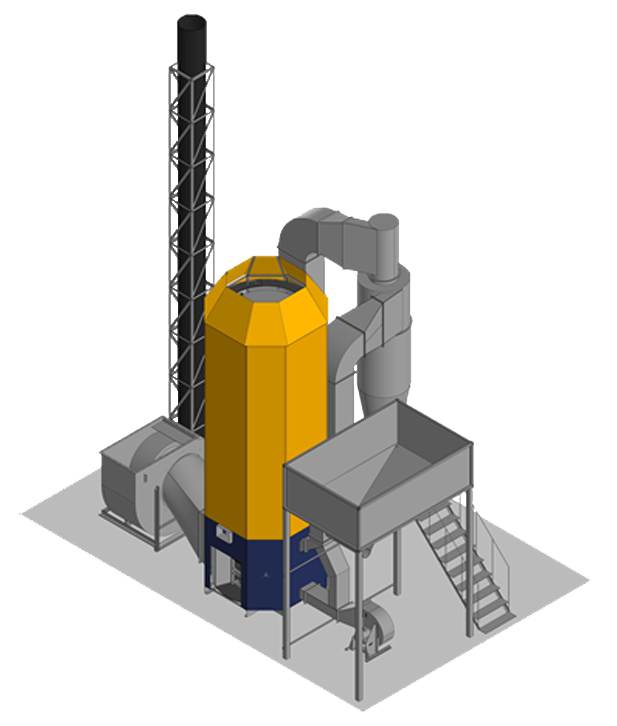

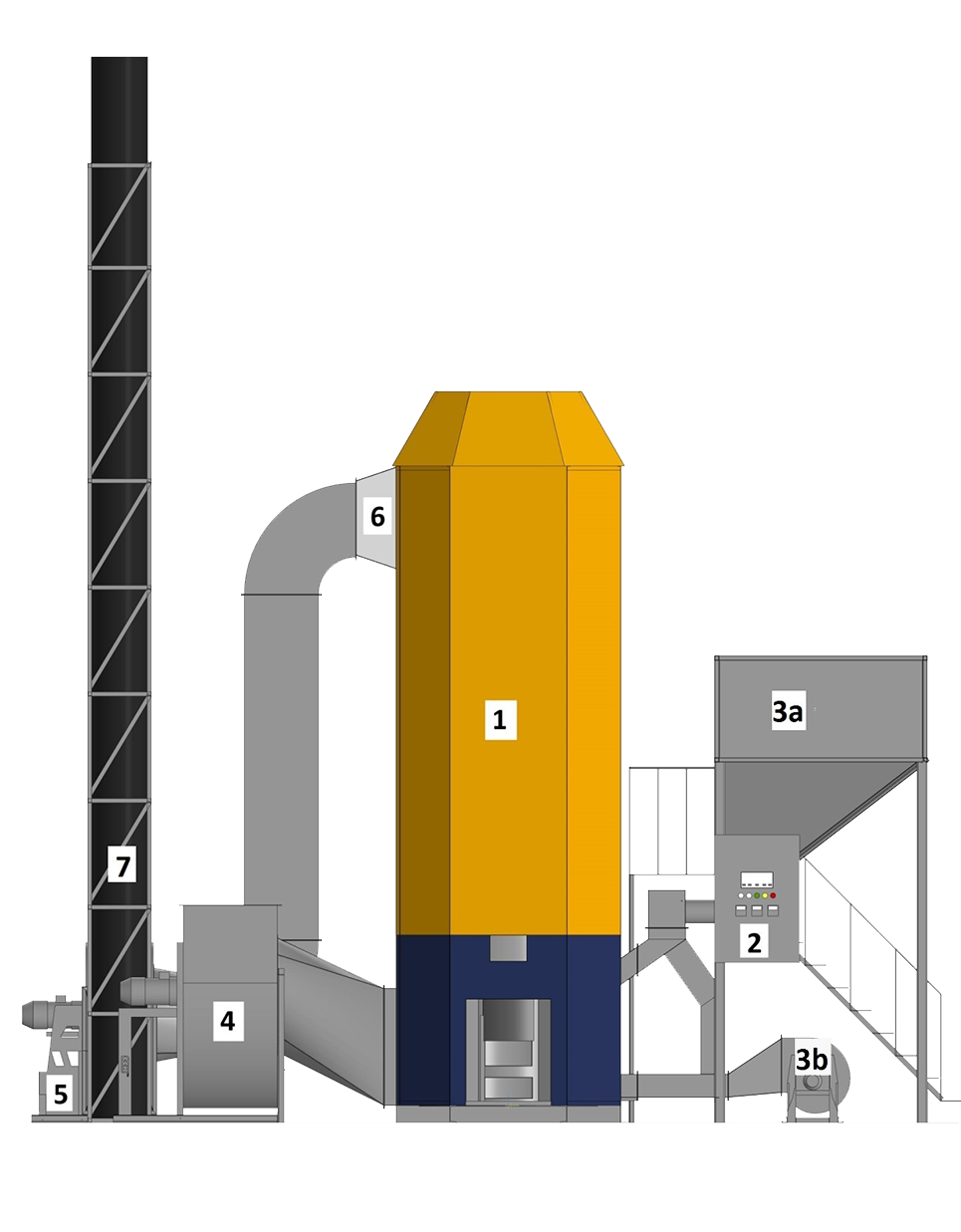

Heat generators for grain dryers

On alternative types of fuel - pellets, wood chips, agricultural waste of sunflower, rapeseed and corn

| Thermal power | 750 kW |

| Hot air output | 27 000 m³/hour |

| Air temperature control range | 50°С - 120°С |

| Installed electrical power | 22 kW |

| Supply voltage | 380 V |

| Weight | 4 tons |

| Installation area | 25 m² |

| Generator bin volume | 3m³ |

| Fuel consumption per 1 t% | 9,0 - 15,0 kg/1t% |

| Productivity for drying corn с 24% to 14% humidity | 2 tons per hour |

| Productivity for drying corn from 20% to 14% humidity | 3,3 tons per hour |

| Fuel type | Pine pellets | Corn stalks | Sunflower stems | Wood chips |

| Consumption (kg/hour) | 183 | 194 | 213 | 315 |

| Consumption (m³/day) | 13 | 14 | 15 | 23 |

| General humidity | 9,9 | 45 | 45 | 40 |

| Lower calorific value | 17,51 | 16,7 | 16 | 10,22 |

| Fuel costs per 1t% | 9,0 kg | 9,6 kg | 10,5 kg | 15,6 kg |

| Fuel type | Pine pellets | Corn stalks |

| Consumption (kg/hour) | 183 | 194 |

| Consumption (m³/day) | 13 | 14 |

| General humidity | 9,9 | 45 |

| Lower calorific value | 17,51 | 16,7 |

| Fuel costs per 1t% | 9,0 kg | 9,6 kg |

| Fuel type | Sunflower stems | Wood chips |

| Consumption (kg/hour) | 213 | 315 |

| Consumption (m³/day) | 15 | 23 |

| General humidity | 45 | 40 |

| Lower calorific value | 16 | 10,22 |

| Fuel costs per 1t% | 10,5 kg | 15,6 kg |

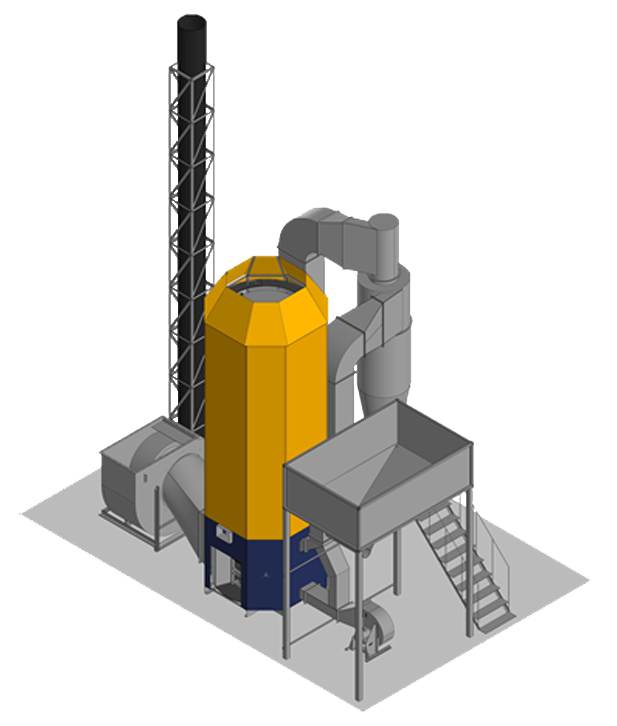

| Thermal power | 1000 kW |

| Hot air output | 36 000 m³/hour |

| Air temperature control range | 50°С - 120°С |

| Installed electrical power | 33 kW |

| Supply voltage | 380 V |

| Weight | 5 т |

| Installation area | 35 m² |

| Generator bin volume | 3m³ |

| Fuel consumption per 1 t% | 9,0 - 15,0 kg/1t% |

| Productivity for drying corn с 24% to 14% humidity | 3 tons per hour |

| Productivity for drying corn from 20% to 14% humidity | 5 tons per hour |

| Fuel type | Pine pellets | Corn stalks | Sunflower stems | Wood chips |

| Consumption (kg/hour) | 243 | 259 | 284 | 420 |

| Consumption (m³/day) | 18 | 19 | 21 | 31 |

| Total humidity, Wr | 9,9 | 45 | 45 | 40 |

| Lower calorific value, Qir | 17,51 | 16,7 | 16 | 10,22 |

| Fuel costs per 1t% | 9,0 kg | 9,6 kg | 10,5 kg | 15,6 kg |

| Fuel type | Pine pellets | Corn stalks |

| Consumption (kg/hour) | 243 | 259 |

| Consumption (m³/day) | 18 | 19 |

| Total humidity, Wr | 9,9 | 45 |

| Lower calorific value, Qir | 17,51 | 16,7 |

| Fuel costs per 1t% | 9,0 kg | 9,6 kg |

| Fuel type | Sunflower stems | Wood chips |

| Consumption (kg/hour) | 284 | 420 |

| Consumption (m³/day) | 21 | 31 |

| Total humidity, Wr | 45 | 40 |

| Lower calorific value, Qir | 16 | 10,22 |

| Fuel costs per 1t% | 10,5 kg | 15,6 kg |

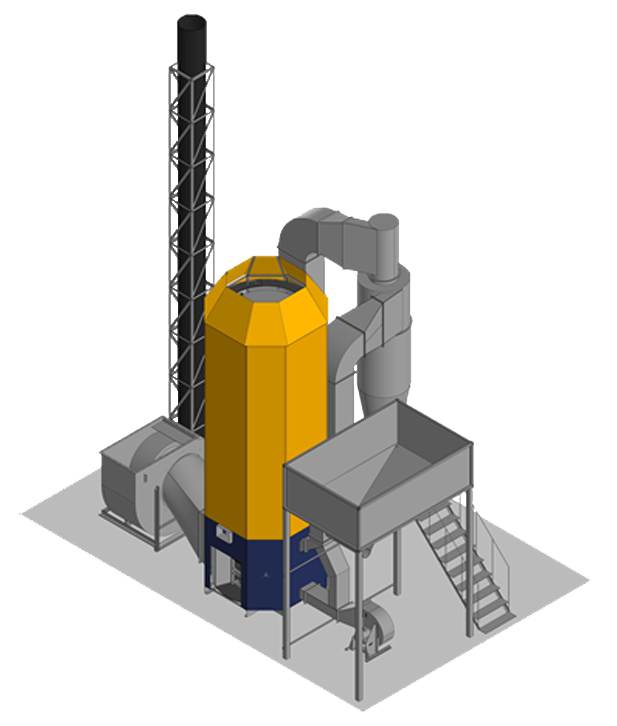

| Thermal power | 1500 kW |

| Hot air output | 54 000 m³/hour |

| Air temperature control range | 50°С - 120°С |

| Installed electrical power | 50 kW |

| Supply voltage | 380 V |

| Weight | 7 т |

| Installation area | 45 m² |

| Generator bin volume | 4,5m³ |

| Fuel consumption per 1 t% | 9,0 - 15,0 kg/1t% |

| Productivity for drying corn с 24% to 14% humidity | 4 tons per hour |

| Productivity for drying corn from 20% to 14% humidity | 6,6 tons per hour |

| Fuel type | Pine pellets | Corn stalks | Sunflower stems | Wood chips |

| Consumption (kg/hour) | 365 | 389 | 426 | 630 |

| Consumption (m³/day) | 27 | 28 | 31 | 46 |

| Total humidity, Wr | 9,9 | 45 | 45 | 40 |

| Lower calorific value, Qir | 17,51 | 16,7 | 16 | 10,22 |

| Fuel costs per 1t% | 9,0 kg | 9,6 kg | 10,5 kg | 15,6 kg |

| Fuel type | Pine pellets | Corn stalks |

| Consumption (kg/hour) | 365 | 389 |

| Consumption (m³/day) | 27 | 28 |

| Total humidity, Wr | 9,9 | 45 |

| Lower calorific value, Qir | 17,51 | 16,7 |

| Fuel costs per 1t% | 9,0 kg | 9,6 kg |

| Fuel type | Sunflower stems | Wood chips |

| Consumption (kg/hour) | 426 | 630 |

| Consumption (m³/day) | 31 | 46 |

| Total humidity, Wr | 45 | 40 |

| Lower calorific value, Qir | 16 | 10,22 |

| Fuel costs per 1t% | 10,5 kg | 15,6 kg |

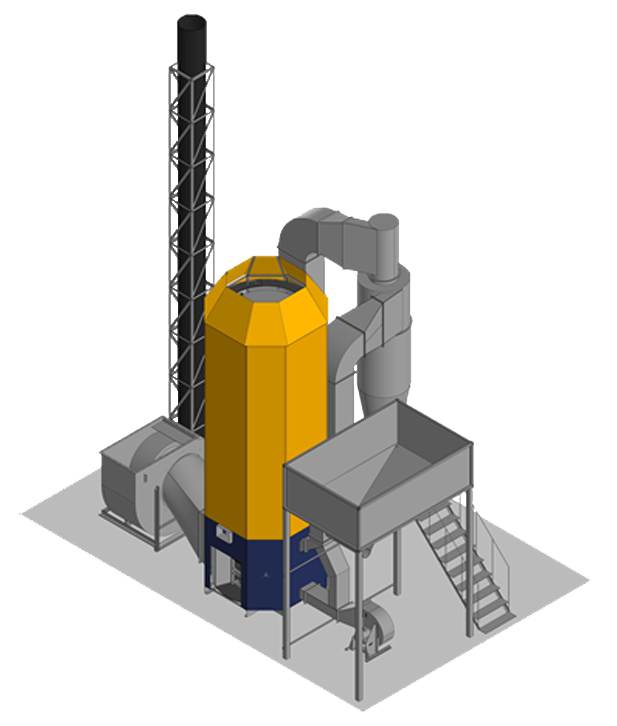

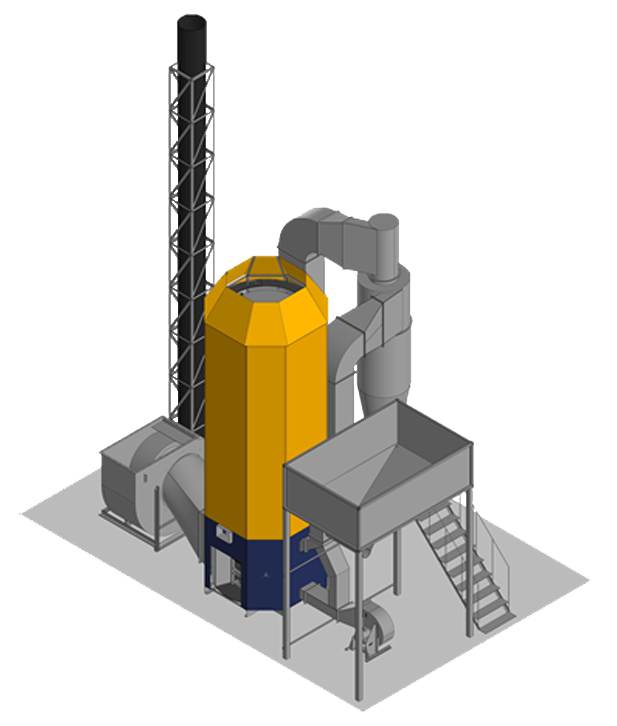

| Thermal power | 2000 kW |

| Hot air output | 72 000 m³/hour |

| Air temperature control range | 50°С - 120°С |

| Installed electrical power | 70 kW |

| Supply voltage | 380 V |

| Weight | 10 т |

| Installation area | 60 m² |

| Generator bin volume | 7,5m³ |

| Fuel consumption per 1 t% | 9,0 - 15,0 kg/1t% |

| Productivity for drying corn с 24% to 14% humidity | 5,5 tons per hour |

| Productivity for drying corn from 20% to 14% humidity | 9,1 tons per hour |

| Fuel type | Pine pellets | Corn stalks | Sunflower stems | Wood chips |

| Consumption (kg/hour) | 487 | 519 | 569 | 841 |

| Consumption (m³/day) | 35 | 38 | 41 | 61 |

| Total humidity, Wr | 9,9 | 45 | 45 | 40 |

| Lower calorific value, Qir | 17,51 | 16,7 | 16 | 10,22 |

| Fuel costs per 1t% | 9,0 kg | 9,6 kg | 10,5 kg | 15,6 kg |

| Fuel type | Pine pellets | Corn stalks |

| Consumption (kg/hour) | 487 | 519 |

| Consumption (m³/day) | 35 | 38 |

| Total humidity, Wr | 9,9 | 45 |

| Lower calorific value, Qir | 17,51 | 16,7 |

| Fuel costs per 1t% | 9,0 kg | 9,6 kg |

| Fuel type | Sunflower stems | Wood chips |

| Consumption (kg/hour) | 569 | 841 |

| Consumption (m³/day) | 41 | 61 |

| Total humidity, Wr | 45 | 40 |

| Lower calorific value, Qir | 16 | 10,22 |

| Fuel costs per 1t% | 10,5 kg | 15,6 kg |

Payback period - 1-3 months due to the use of wood chips or biowaste from the collection and cleaning of wheat, sunflower, soybeans, corn, etc.

Low cost of hot air for drying due to the use of cheap biofuel and the design features of the heat generator. The cost of drying 1t% is 10 times less than the cost of drying with gas.

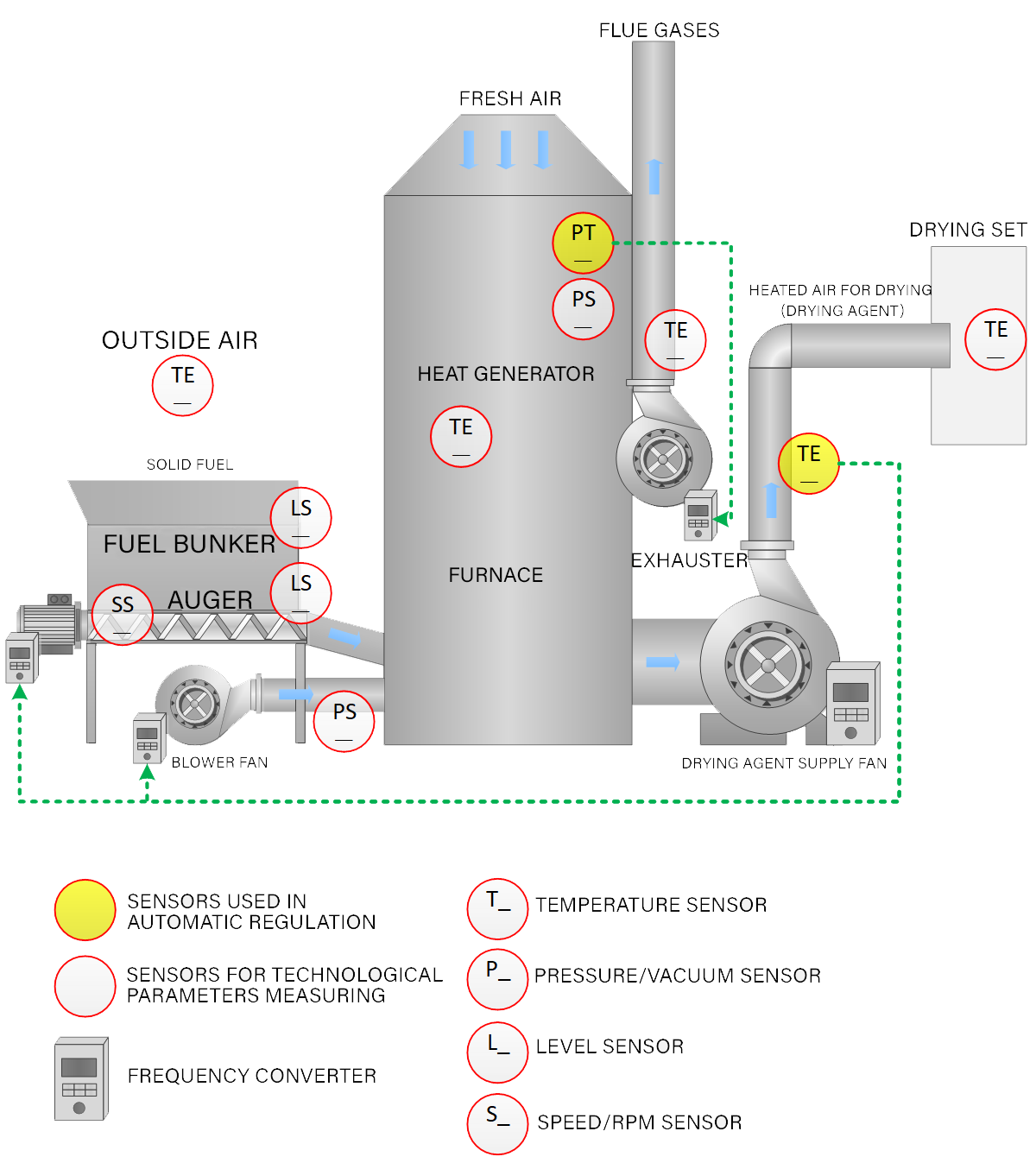

Air heating up to +120 ° C. Efficiency up to 80-85%. Ensuring high combustion efficiency even of low-quality fuel (wet chips, as well as low-calorie waste of agriculture and wood processing) thanks to the innovative design of the furnace and automatic regulation of air pressure and pressure in the furnace.

Heat generators DAN AGRO process unwanted bio-waste into ash, which can then be used as fertilizer. Thanks to the built-in heat exchanger, the grain is dried using clean air. High quality cleaning of flue gases eliminates contact of grain with combustion products.

Heat generators DAN AGRO are made of high-quality European materials and components. Due to the design features, they have an increased service life compared to generators from other manufacturers.

Heat generators DAN AGRO can be used for grain dryers of different types. Technical solutions used in these heat generators allow to use wood chips and waste from the collection and cleaning of agricultural crops as fuel.

Save on fuel costs by 10-15 times

Short payback period: 1-3 months

Heat generator is designed to heat air up to +120°C

Effectiveness and environmental friendliness. The design of the heat exchanger eliminates contact of grain with combustion products

Can be used for grain dryers of different types

Manufactured from high-quality European materials and components

Due to the design features, it has an increased service life compared to heat generators from other manufacturers

* insurance in case of losses associated with the occurrence of a warranty event

Automatic self-heating of the generator and maintenance of the set air temperature

Efficient biofuel combustion according to the settings

Control and notifications about the fuel level in the bunker

Remote monitoring and change of the set temperature (from a smartphone, tablet or PC)

Simple and convenient graphical interface on a color touch screen

Automatic system for blocking and protecting the heat generator and key units

Ukraine, 03035,

Kiev, Solomyanskaya square, 2

Ukraine, 08113,

Kiev region,

Petrushki village, Mira Street 25В